- The investments support production of the Cadillac Escalade, Chevrolet Silverado and GMC Sierra as well as the Chevrolet Equinox and the Chevrolet Bolt EV.

- All of GM’s recent production changes have been geared towards streamlining and consolidating its vehicle production in the U.S.

General Motors is investing $550 million into components plants in Michigan and Ohio to gear up for increased vehicle production in 2027.

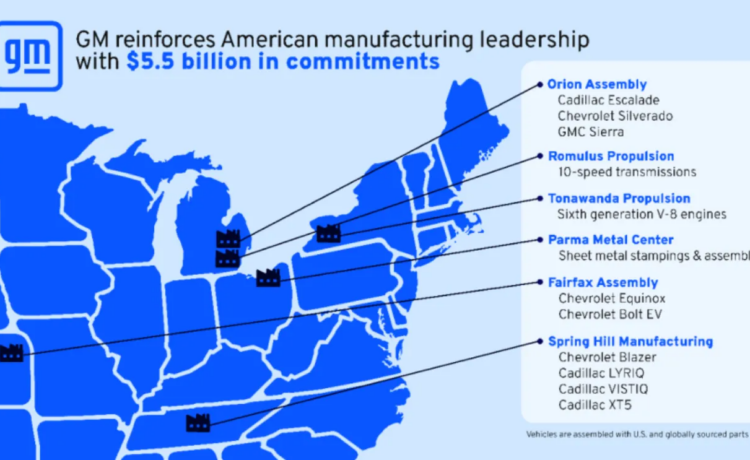

GM confirmed to the Detroit Free Press on Nov. 24 that $300 million is slated for Romulus Propulsion Systems to produce 10-speed transmissions for full-size pickups and SUVs. The other $250 million going to Parma Metal Center near Cleveland, Ohio, is to make sheet metal stampings and assemblies.

The investment in Parma is expected to create 100 jobs, according to GM spokesman Kevin Kelly, though no increase in employment is expected for Romulus.

In particular, the latest investments support production of the Cadillac Escalade, Chevrolet Silverado and GMC Sierra at Orion Assembly in Michigan as well as the Chevrolet Equinox and the Chevrolet Bolt EV at Fairfax Assembly in Kansas.

Mike Trevorrow, senior vice president of global manufacturing, said in a Nov. 20 statement that the money is earmarked for upgraded equipment as well as “investing in the people who make it all happen.”

“Our manufacturing teams are the driving force behind GM’s success, and we’re committed to giving them the tools and training they need to excel in today’s advanced manufacturing world,” Trevorrow said. “When we invest in our workforce, we’re not only building great vehicles — we’re helping secure the future of American manufacturing.”

Parma Metal Center can produce over 100 million parts annually, GM also said. The site can process more than 400 tons of steel daily that go into parts for most of GM’s North American-built vehicles.

The investments support the increased U.S. manufacturing plans that GM laid out this summer. GM said in June it would invest a historic $4 billion in three U.S. plants ― Orion Assembly in Michigan, Fairfax Assembly in Kansas and Spring Hill Manufacturing in Tennessee ― which involved moving production of gasoline-powered vehicles up from Mexico like the Chevrolet Blazer.

The latest investment, when combined with the landmark $888 million slated for its Buffalo, New York, engine plant, boosts GM’s total planned U.S. manufacturing spend to nearly $5.5 billion. GM said May 29 that the New York investment for the next generation V-8 engine marked the automaker’s largest-ever investment in a propulsion plant.

All of GM’s recent production changes have been geared toward streamlining and consolidating its vehicle production in the U.S. Avoiding tariffs is a primary motivating factor, as GM noted in May that President Donald Trump’s tariffs on imported vehicles and auto parts will likely cost the company $5 billion this year. Relocating production to the U.S. is just one of the “self-help” policies that GM executives say will help mitigate tariff costs and fortify its supply chain.

Jackie Charniga covers General Motors for the Free Press. Reach her at [email protected].